V12 Cruise Control Bellows

This note is about the rather unreliable bellows actuator on the pre-1991 V12.

The actuator comprises a rubber bellows, an expansion spring and two steel endplates, one of which incorporates two 12 volt electric solenoid vacuum valves. It is located in the centre of the engine’s “V”, and is bolted to a plate attached to the end of the aircon compressor.

Valve “A” is normally closed, but when operated by the cruise system it allows vacuum to the bellows. Valve “B” is a safety valve and is normally open, allowing any vacuum in the bellows to escape. Valve B needs to be closed electrically to shut off this vacuum escape, upon which if Valve A is operated vacuum is applied to the bellows which contracts, pulling a cable which opens the throttle.

When cruise is operational, the controller switches Valve B on, and switches valve A on and off alternately to achieve an average position of the endplate and thus throttle cable to achieve the engine speed required.

If cruise is switched off (by turning it off or hitting the brakes) valve A is turned off thus shutting off vacuum to the bellows, and valve B is turned off releasing the vacuum to atmosphere and so the bellows relax to the fully expanded condition.

On later cars circa 1985 – 1991 there is an additional safety feature which is another electric vacuum valve to switch off vacuum to the Valve A – which could stick open. See pic below for location (on forward end of RH bank manifold).

Faults:

The most obvious sympton of failure is when the engine speed is not maintained when pressing the cruise “set” control. This is nearly always due to a fault in the bellows.

The most common reasons are:

- Poor seal between rubber bellows and the endplates

- One or both vacuum valves stuck in position

- Vacuum pipe fallen off inlet port to valve A

- Cable from bellows broken or maladjusted.

Test bellows as follows:

- Disconnect throttle cable from bellows end plate.

- Connect vacuum inlet hose (on Valve A) to a source of vacuum which could be from an inlet manifold with the engine running.

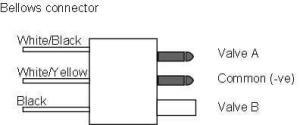

- Disconnect 3 way connector on short harness from bellows.

- Apply 12 volts (polarity doesn’t matter) across outer two terminals. This should operate both valves, albeit with only 6 volts each as they are now in series – but this checks that they operate well on reduced voltage.

- Vacuum should now arrive at the bellows and with valve B operated it won’t escape.

- The bellows should contract fully in about 5 seconds depending on the vacuum source.

Fixes:

To re-seal the bellows, dismantle the unit (having removed it from the car) by pulling off the end plates – note there is a big but not very strong spring in the middle.

Don’t forget to put this back when you re-assemble!

Thoroughly clean the grooves in the ends of the bellows where the endplates sit.

Most adhesives don’t work well in this application so cleanliness is essential. Use a powerful degreaser.

Similarly clean the edges and rims of both endplates.

Apply sealant to the inside of the bellows groove, insert valve endplate and twist it around a bit to spread the sealant.

Put in the spring making sure it’s located on the raised pips on the valve plate, and insert other plate, twisting as before.

Allow to set.

Sealants:

It’s tempting to use general purpose silicone sealant but we find it doesn’t stick very well – either to the rubber or the metal. There are specialist silcone sealants that may be better. We use a professional mastic glue called Bond and Seal from Wurth which is very good.

Failing that, EvoStick or similar flexible contact adhesive may do well enough but as you won’t be able to twist the endplates make sure you have enough glue evenly spread.

Sticking Valves

These are very difficult to repair and they’re very difficult to get out of the backplate into which they have been glued originally. But it can be done and you have little to lose by trying – if you’re sure one or both of the valves is actaully faulty. The central plunger may be stck due to corrosion, or the valve pads may be distorted or missing. It’s really much simpler to buy a good second hand bellows unit and recondition it by sealing the bellows.

If you found this article helpful please hit the like button below to let us and others know.